How do electric vehicle designs differ from traditional ICE vehicle designs?

Electric vehicles (EVs) differ from internal combustion engine (ICE) vehicles in several ways due to the differences in their propulsion systems and energy storage requirements. Key design differences include:

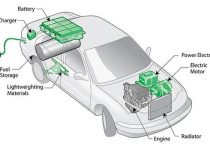

- Powertrain: EVs use an electric motor (or motors) for propulsion, which is simpler and has fewer moving parts compared to an ICE. This can lead to reduced maintenance and improved reliability. EV powertrains also do not require components such as a fuel tank, exhaust system, or multi-speed transmission, which further simplifies the design.

- Energy storage: EVs use a battery pack to store energy, which is typically located in the floor of the vehicle or in a centralized location for optimal weight distribution. This can lead to a lower center of gravity, resulting in improved handling and stability.

- Packaging and space utilization: With fewer components and a more compact powertrain, EV designers have more freedom to optimize interior space and vehicle layout. This can result in increased passenger and cargo room, as well as novel design approaches such as “skateboard” platforms that allow for greater design flexibility.

- Cooling systems: Electric vehicles require different cooling systems compared to ICE vehicles. EVs need thermal management systems for the battery pack and electric motors, while ICE vehicles require cooling for the engine and transmission. This difference can affect the design and placement of cooling components, such as radiators and heat exchangers.

- Aerodynamics: To maximize range and efficiency, EV designs often place a greater emphasis on aerodynamics. This can lead to smoother body shapes, enclosed front grilles, and streamlined underbodies that minimize air resistance.

- Regenerative braking: EVs often incorporate regenerative braking systems that capture energy during deceleration and use it to recharge the battery. This can result in different brake system designs and can affect the overall driving experience, as drivers may need to adapt to the feel of regenerative braking.

- User interface and controls: Many EVs incorporate digital displays and touchscreens to provide information on battery charge levels, range, energy consumption, and charging status. These interfaces can replace or supplement traditional instrument panels and may include additional features such as charging station location and route planning.

- Noise and vibration: Electric motors produce significantly less noise and vibration than internal combustion engines. This can affect the design of the vehicle’s noise insulation and vibration damping systems, as well as the overall driving experience.

While there are notable differences between electric vehicle and ICE vehicle designs, some similarities remain, such as the use of lightweight materials, safety systems, and overall vehicle structure. As electric vehicle technology continues to advance, it is likely that design innovations will further differentiate EVs from their ICE counterparts.

- Electric motor placement: In EVs, electric motors can be placed in various configurations, such as near the axles, in-wheel, or between the wheels. This flexibility allows for different drivetrain setups, including front-wheel drive, rear-wheel drive, or all-wheel drive, and can affect vehicle handling, weight distribution, and available interior space.

- Charging ports: Electric vehicles require charging ports for connecting to charging stations, which are typically placed on the side or front of the vehicle. This necessitates additional design considerations, such as port placement, accessibility, and integration with the vehicle’s body.

- Reduced weight of ancillary components: Since EVs don’t require certain components found in ICE vehicles, such as exhaust systems, fuel tanks, and multi-speed transmissions, the overall weight of the vehicle can be reduced. This allows designers to focus on using lightweight materials to further optimize vehicle efficiency, performance, and handling.

- Software integration: Electric vehicles often have more advanced software systems that control various aspects of the vehicle, such as battery management, thermal management, and driving modes. The increased reliance on software can lead to more sophisticated vehicle designs that include over-the-air updates, remote diagnostics, and predictive maintenance.

- Safety considerations: With high-voltage battery systems, EV designs need to incorporate safety features to protect occupants and first responders in the event of an accident. This may include reinforced battery enclosures, fire suppression systems, and high-voltage disconnect systems that automatically shut down the battery in case of a collision or other emergency.

- Electromagnetic compatibility (EMC): Electric vehicles generate electromagnetic fields due to the high currents and voltages used in their systems. Designers must consider EMC in the vehicle’s layout, shielding, and grounding to minimize interference with other electronic systems, both within the vehicle and in the surrounding environment.

Despite these design differences, electric vehicles still share some commonalities with traditional ICE vehicles, such as the need for suspension systems, brakes, tires, and body structures. However, the unique aspects of electric vehicle designs offer the opportunity to create more efficient, sustainable, and innovative transportation solutions that can redefine the future of personal mobility.